When Capability Leaves, It Doesn't Come Back: What Small Business Loss Actually Costs

The pattern is becoming familiar

A customer walks into a small retail shop. They ask questions, handle products, get ideas from the owner's expertise. Then they go home and order a cheaper imported version online.

In renewables, specialist engineering firms that maintain and repair wind turbine components are being squeezed out. This is not because they're incompetent, but because it's cheaper in the short term to replace parts with new imports than to maintain equipment properly.

Is this just retail trends or market forces? What happens to a place when the businesses that hold deep capability close their doors.

What we're actually losing

Australia recorded 370,500 business exits in 2024–25, alongside 437,150 entries. Business churn is normal in a dynamic economy. But when the exiting businesses are creative makers, technical specialists, and deep experts, what leaves with them isn't easily replaced by "another business opening somewhere else."

These businesses hold things the economy depends on but struggles to measure:

Creative originality – Design literacy, craftsmanship, authorship. The ability to create something new rather than copy what exists.

Specialist technical knowledge – Diagnostics, maintenance, repairs, safety-critical judgment. The accumulated wisdom that comes from solving the same class of problems hundreds of times.

Local supply chain resilience – The capacity to fix, adapt, and keep systems running when global supply chains fail or tighten.

Skills transfer – Apprenticeships, mentoring, tacit knowledge that can only be passed from one person to another over time.

When these businesses shut down, communities lose more than shops or services. They lose capability and they become more dependent on systems they don't control.

The economics are working against capability

The modern economy has trained buyers, both consumers and large organisations, consciously or unconsciously, to optimise for:

Upfront price over lifecycle cost

New over repaired

Cheap copies over authentic authorship

Replacement over resilience

This may be traced back to the 1950s, perhaps the first time in human history where we disposed of something that was still working and reinforced through the decades as we’ve got better at mass production to reduce costs.

But this is having a devastating impact on small businesses who are built on originality and expertise. They get crushed, even when they're creating more long-term value, in our instant gratification world.

This is impacting all sizes of business and whilst it is natural to see evolution of industries, what is the long term cost. Take the renewables example, operations and maintenance can represent around one-third of a wind power plant's lifecycle cost, according to research from the National Renewable Energy Laboratory. That means decisions that under-invest in maintenance expertise aren't "saving money"—they're shifting cost into downtime, reliability issues, and future replacement cycles.

This isn't only an engineering problem. It's a procurement and incentives problem. The system rewards the wrong things.

What small businesses can do to survive this

Businesses built on deep capability can't compete on unit price. They shouldn't try. What they can do is fundamentally change what they're selling.

Stop selling things. Start selling outcomes.

I don’t have the solutions, however, if we consider that the copied, mass produced, cheaply made product loses when the real value isn't the object, it's the relationship, process, accountability, and trust.

For creatives: Shift from selling finished products to selling commissioned work, limited runs with provenance, process access (behind-the-scenes storytelling), and customisation as standard. You can copy a product. You can't copy authorship plus intent plus relationship.

For technical specialists: Sell diagnostics, outcomes, assurance, customisation, and long-term service relationships rather than one-off transactional jobs. The value isn't "we can do this task." The value is "we know how to diagnose and solve this class of problem."

For Service based businesses: Do what small businesses do best, be more human.

It’s risky when the world is still focused on cheap and quick, but we’re starting to see change.

Build "can't be copied" moats* deliberately

*An Economic Moat is a business’ ability to maintain a competitive advantage.

Small businesses need defensibility, not scale foundationally. That means:

IP tied to service delivery, not product specifications

Certification and training pathways

Proprietary diagnostic processes

Embedded data and insight from years of work

If the core value is deep knowledge and judgment, cheap imports become irrelevant. It’s then about educating the client/customer about why this is better. And by educate, we need to show them. Not your process, necessarily, the results, the outcomes.

Price for capability, not hours

Many specialists under-price their knowledge because they're billing for time rather than for the years of experience that enable them to solve problems quickly. The pricing question isn't "how long did this take?" It's "what's the cost if this problem isn't solved correctly?"

Consider value-based pricing models, which are set based on the perceived value to the customer.

We may have all heard the story (or a version of it) about the factory whose engine had stopped working and paid a number of cheap contractors to come and repair it. They spend days dismantling the engine to not be able to find the problem, during which time production was stalled impacting the factory financially. Finally, the owner brings in an expert who walks in with a spanner, looks at the engine, touches it a few times and then whacks it with the spanner. The engine rumbles and starts working again. The expert sends an invoice for $10,000. The owner tries to negotiate saying that the expert only hit the engine with a spanner, however, the expert explains that the owner wasn’t simply paying for the action, he was paying for the significant experience and education to know exactly where and how to hit the engine with the spanner.

What communities and governments can do to keep capability local

If we want resilient local economies, we need to rebuild the conditions that allow capability-based businesses to survive.

1. Procurement must shift from cheapest to whole-of-life value

Governments and large buyers can move markets quickly by adopting whole-of-life costing practices, explicitly including maintenance, reliability, downtime, and end-of-life costs. South Australia has published practical guidance describing whole-of-life costing as total costs across acquisition, operation, maintenance and disposal.

When tenders reward lifecycle value rather than upfront price, it creates space for local maintainers, refurbishers, and specialists to compete fairly.

2. Make repair and maintenance economically visible

We can't preserve technical capability if repair is treated as an "optional extra" that's always more expensive than replacement.

Several countries have recognized this and are testing interventions that work:

Sweden reduced VAT on certain repairs (bikes, clothes, shoes), explicitly aiming to make repair a more rational economic choice than replacement.

Austria introduced the Reparaturbonus (repair bonus) to subsidize repairs. Published research shows very high voucher redemption; evidence that consumers will choose repair when friction and cost are reduced.

France introduced a mandatory repairability index from January 2021. A score shown to consumers for specific categories of electronics and appliances. Even where evaluation of outcomes is still emerging, the mechanism matters: labeling helps shift purchasing away from "cheap now, replace soon" toward durable, repairable products.

Australia's Productivity Commission has identified "significant and unnecessary barriers to repair" for some products and proposed measures to improve repair outcomes. The European Union adopted the Directive on common rules promoting the repair of goods in June 2024, requiring member states to apply it from July 2026.

These are small business enablement policies as well as environmental policies and keeping independent repairers viable, expanding service ecosystems, and building resilient local capability.

3. Treat specialists as capability infrastructure, not vendors

Technical specialists fail when they're treated like "just another supplier" competing job by job. They survive when they're treated as strategic capability.

Models that stabilize capability include:

Retainers

Standing panels of specialists

Service subscriptions

Cooperative shared-services arrangements

This is how you keep expertise in-region and ready when supply chains fail, equipment breaks, or standards tighten.

We are seeing an increased focus on engaging small businesses in procurement from Federal, State and Local governments in Australia. The procurement team of Brisbane 2030 have been vocal about their support for small business through the process. However, these small businesses are not always as experienced in the tender or procurement process and providing additional support and guidance to increase capability to apply for work packages would increase the equity of access and increase the success rate of small businesses to win the work.

4. Support repair and maintenance ecosystems, not one-off initiatives

A functioning repair economy requires:

Repair vouchers (targeted to categories aligned with local capability)

Business capability uplift for repairers (digital systems, quoting, compliance)

TAFE and industry micro-credentials for specialist maintenance

A visible "local repair map" for residents and businesses

This turns scattered micro-firms into a recognized sector that can attract both customers and new entrants.

This is a small act, however, this shifts local sentiment from a ‘buy cheap online’ to ‘I can get this repaired conveniently’

5. Protect creatives from becoming unpaid R&D

When customers use small businesses as showrooms and then buy copied imports online, creatives are functioning as unpaid research and development for global manufacturers.

Practical interventions could include:

Showcase local artists and makers so more people see their work and realise they’re locals, encouraging them to buy and why it is important to support locals.

Share education about why supporting local matters, show the relationship between spending locally and how that helps where they live, so they can make the connections. Without shaming, share the impact not having local businesses would have.

"Designed <your region/here" certification that protects and elevates original design value

Accessible IP and licensing pathways (templates, office hours, low-cost legal clinics for creatives)

Gift card programs and local marketplaces that reduce friction for buying local.

6. Use the circular economy framework strategically

Australia now has a national Circular Economy Framework that explicitly points communities toward local circular initiatives such as repair cafés and reuse models. States including Victoria and Queensland are funding circular economy activity through grant programs.

This matters because it reframes repair, reuse, and local capability as economic development levers, not just environmental programs. Economic developers can harness this momentum by embedding repair and maintenance into broader resilience and workforce strategies.

Why this matters: the creatives and specialist infrastructure

Australia's cultural and creative sector contributed $67.4 billion in 2023–24 (2.5% of GDP). At a state level, Victoria reported the creative economy contributed $41.2 billion in 2023–24.

When creative businesses get hollowed out by copying and price pressure, we're weakening a substantial part of the economy, along with the originality and design capability that feeds innovation across other industries.

The same logic applies to technical specialists. When we allow repair and maintenance capability to collapse, we're not just losing "a few small firms." We're actively undermining circular economy goals, resilience, and skilled jobs.

Global circular-economy research consistently positions repair, maintenance, reuse, and remanufacturing as core activities that reduce resource demand and support job creation. Emerging research modeling repair incentives finds that subsidies can increase formal repair expenditure and employment.

The waste implications are enormous. The Global E-waste Monitor 2024 forecasts that documented collection and recycling rates may decline by 2030 even as e-waste rises. Australia's own e-waste challenge has been widely reported, underscoring how quickly replacement cycles create material waste and lost value.

What's at stake

The real question isn't whether a small business can compete with cheap imports. It can't, and it shouldn't have to.

The question is: what kind of economy do we want?

One built to replace, or one built to last?

One that is creative and has a wealth of specialism or one only full of major brands squeezing creativity out?

If we want resilient communities, we need to protect the conditions that allow people with deep capability to stay and build businesses (or trade in a way that makes sense in our future economy).

What we could do now to support our small business community is:

Be mindful of all purchases (personal and business) and the impact you making that purchase has. Is cheaper always better?

Support small businesses that start to do business differently. It may take longer and may cost more initially, however, look at the lifecycle cost and/or future value

Changing procurement rules so lifecycle cost and resilience are counted

Treating creative, technical and specialist capability as essential infrastructure and embed it into policies and strategies.

We may not have all of the answers and it is a complex subject in which some may argue that we may not need these skills in the future, however, the world would be a lot less colourful and innovative without them. If this matters and we want a colourful and innovative future,, the solution is to build an economy that actually rewards the value they create.

Because when capability leaves, it doesn't come back. And once it's gone, we will feel the loss as a society long after we've forgotten the savings.

Note from Sam:

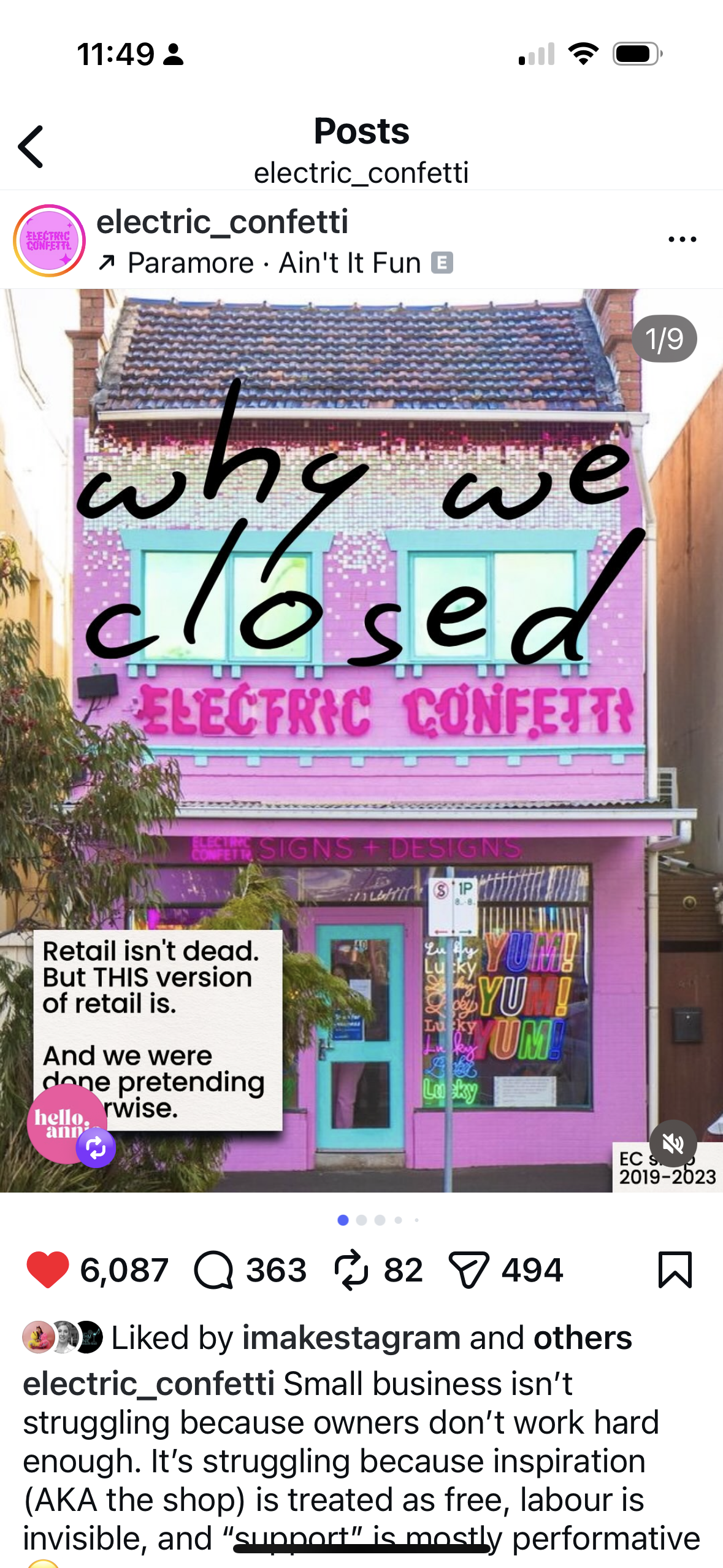

The post that inspired me to write this was by Electric Confetti, a brightly coloured store we pass on the way to my husband's parents. It screams fun and brightens your day, even without going inside.

However, that's the challenge. If we never buy or (even worse) if we go in and then buy a cheap copy online, we could be building a future that isn't so bright.

This particular business has decided to close the shop front, for a number of reasons, however, buying cheap copies only and increasing rent were two of them.

I studied the Japanese Edo Period and its impact on economic development at University. During this time, limiting imports allowed for 'sapling' industries to strengthen before being exposed to foreign competition, while also fostering rapid technological advancement. This may have influenced my thinking and i'm not suggesting we move our government to control imports! But, I do think there are things we can all do to ensure our future is capable and creative.

I've suggested strategies for the small businesses, including limiting their products/services 😵 , focusing on what they can uniquely provide and helping clients/customers understand that.

I've also suggested what economic development practitioners (in all levels of government) might consider. Procuring small businesses is getting better, however, there may be more we could do at a local level that could make a huge difference.

I don't have the answers, but I'm driven by the future I want to see.

And for those who may think that doesn't impact them, I'd invite a moment of reflection.

What kind of future would you like to see?

Is it colourful and innovative?

Capable?

I hope these questions help when you're making purchasing decisions.

References

Electric Confetti Instagram Post https://electricconfetti.org/

Australian Bureau of Statistics (2024-25). Business entry and exit data.

National Renewable Energy Laboratory. Operations and maintenance lifecycle cost analysis for wind power plants.

South Australia Government. Whole-of-life costing guidance for procurement.

Australian Productivity Commission. Right to Repair inquiry and recommendations.

European Union (2024). Directive on common rules promoting the repair of goods. Adopted June 2024, entered into force July 30, 2024.

Sweden. VAT reduction on repair services policy.

Austria. Reparaturbonus (repair bonus) program and redemption data.

France. Mandatory repairability index legislation (January 2021).

Australia Department of Climate Change, Energy, the Environment and Water. National Circular Economy Framework.

Victoria State Government. Creative economy contribution data (2023-24): $41.2 billion.

Australian Government. Cultural and creative sector contribution (2023-24): $67.4 billion, 2.5% of GDP.

Global E-waste Monitor (2024). Forecast data on collection and recycling rates.

Circular economy research: repair, maintenance, reuse and remanufacturing as job creation activities.